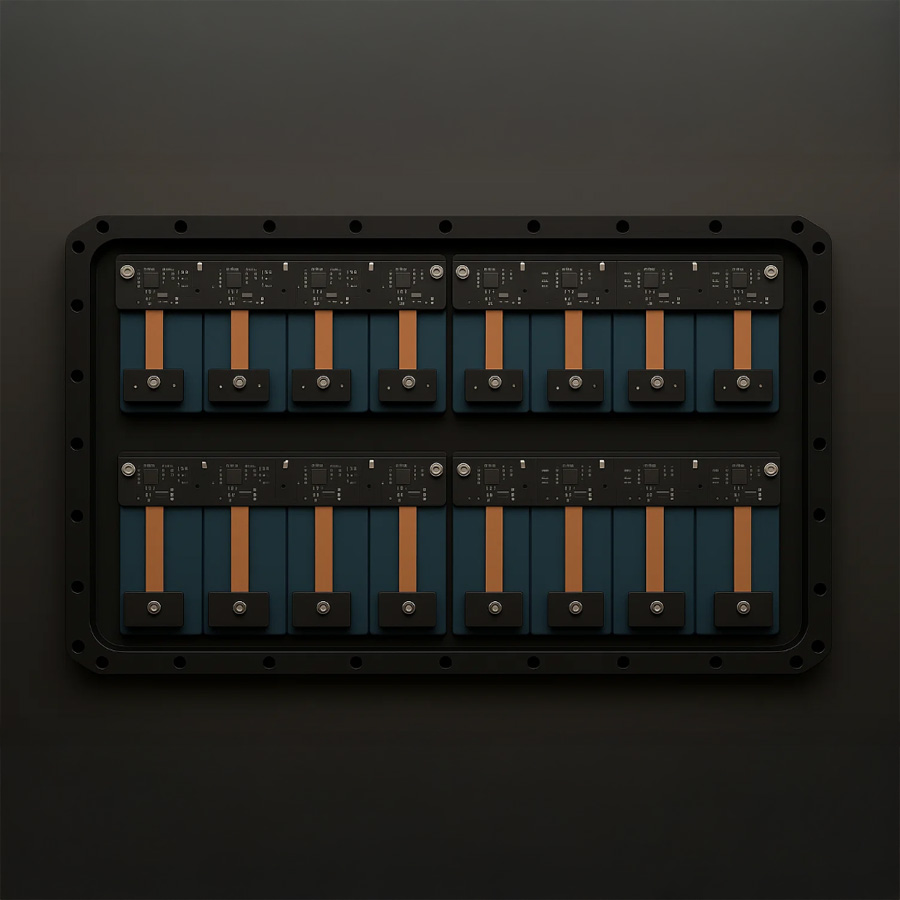

Custom BMS Development

We specialize in the development of custom Battery Management Systems (BMS) tailored to the unique requirements of your energy storage needs from stationary (BESS) to mobility (drones, EVs, and marine applications).

Precision Monitoring and Control

Our custom BMS hardware enables real-time measurement and control of battery voltage, current, and temperature. It calculates State of Charge (SoC) and State of Health (SoH) with high accuracy, ensuring optimal battery performance and extending system lifespan.

Built-In Safety Features

Every CRATUS/Intercal8 BMS includes integrated safety protections against overcharge, over-discharge, short circuits, thermal runaway, and cell imbalance. These core functions are continuously monitored and actively managed in real time to ensure the battery system operates within safe electrical, thermal, and chemical limits.

To support deployment in critical applications, our BMS designs are developed with safety certifications and compliance in mind. Systems can be engineered to comply with standards such as:

UL 9540 – For energy storage systems and equipment, ensuring the entire system (BMS + battery + enclosure) meets rigorous fire safety and performance requirements.

UL 1973 – Specifically for stationary battery applications, validating the battery module’s construction, performance, and safety.

IEC 62619 – For industrial lithium battery safety, commonly required for international deployments.

ISO 26262 (optional) – For functional safety in automotive-grade applications when required.

These standards validate not just the safety of individual components, but also the system-level interactions, fault management, and thermal behavior. We design our BMS to be compliant-ready and support certification processes through detailed documentation, traceability, and test data. This enables our customers to meet regulatory requirements faster and deploy energy storage systems with confidence in residential, commercial, industrial, and transportation sectors.

Wireless BMS Systems

At intercal8, we implement wireless communication in BMS architectures to reduce wiring complexity and connector reliance, improving system reliability and modularity. These systems are suited for applications with distributed batteries, fast assembly requirements, or compact designs—such as specialty vehicles and mobile energy platforms.

We use low-latency communication modules based on the IEEE 802.15.4 standard, with channel diversity and error correction. Sourced from proven industrial suppliers, these modules maintain stable communication between battery packs, PDUs, and site controllers, even in electrically noisy or space-constrained environments.

Eliminating harnesses and long signal paths reduces material cost and system weight while avoiding connector wear, misalignment, and routing errors. Fewer manual insertions and terminations also shorten assembly time and reduce testing overhead.

Our wireless BMS also supports over-the-air diagnostics, firmware updates, and system topology awareness. This allows reconfiguration without physical rewiring, making the solution scalable and easier to deploy in dynamic energy storage applications.

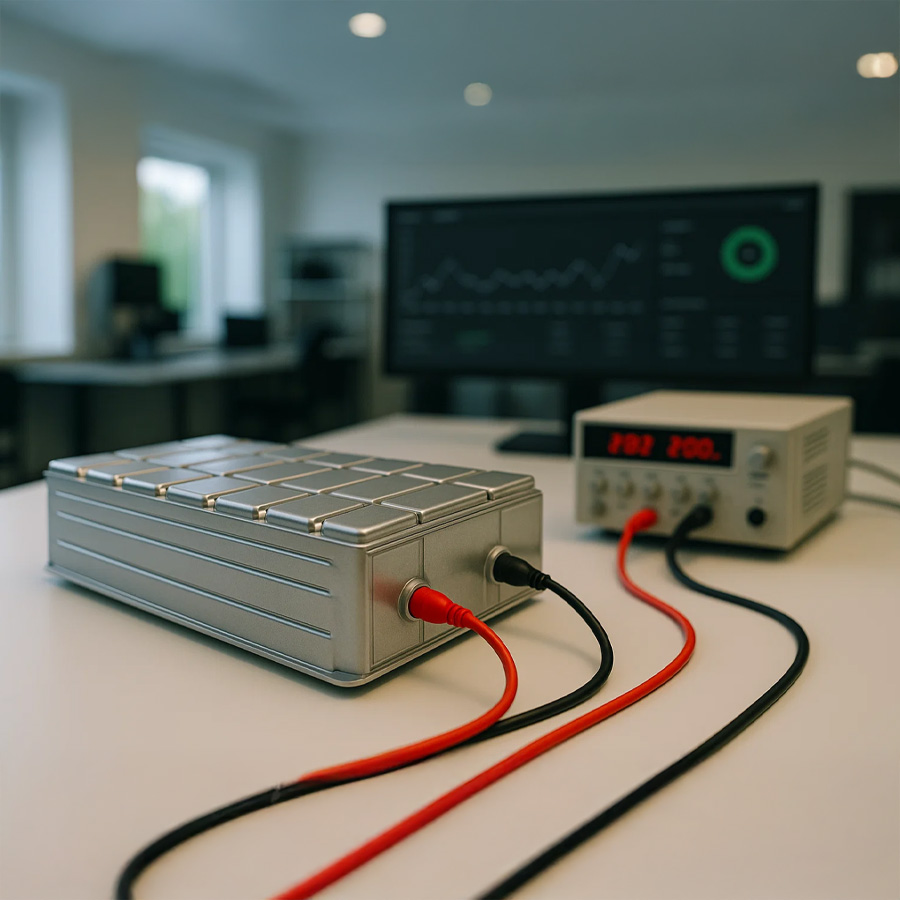

Battery Health and Predictive Maintenance

We design our BMS platforms with continuous diagnostics and predictive maintenance at their core. Each system continuously monitors voltage, current, temperature, internal resistance, and state-of-health (SoH) across individual cells and modules. These high-resolution data streams feed into onboard algorithms that assess battery degradation, cycle life performance, and thermal behavior in real time.

Our predictive maintenance models use trend analysis and fault pattern recognition to identify anomalies long before they escalate into failures. This enables proactive servicing, reducing unplanned downtime, extending battery lifespan, and minimizing operational disruptions.

Key benefits include:

Early Fault Detection: Spotting trends in cell imbalance, capacity fade, or rising internal resistance before they impact system performance.

Maintenance Planning: Supporting data-driven scheduling of service and cell/module replacements based on actual usage and degradation—not assumptions.

Remote Diagnostics: Enabling secure access for service teams to monitor system health, log critical events, and identify problems without dispatching field technicians.

Cost Reduction: Lowering long-term maintenance costs by avoiding catastrophic failures and improving reliability across the deployment lifecycle.

Whether deployed in energy storage, e-mobility, or critical infrastructure, our advanced monitoring ensures your battery systems remain healthy, safe, and efficient — delivering maximum value over their full operational life.

Seamless Integration with Chemistries and Systems

Our BMS platforms are engineered for compatibility with a wide range of battery chemistries, including Lithium Iron Phosphate (LFP), Nickel Manganese Cobalt (NMC), Lithium Titanate (LTO), Lithium Manganese Oxide (LMO), Lithium Cobalt Oxide (LCO), and custom blends. Each chemistry has unique voltage profiles, thermal behavior, and safety thresholds, and our architecture adapts accordingly through tunable control parameters and firmware-level safeguards. This ensures safe and optimized operation for any selected battery type across residential, commercial, and industrial deployments.

Beyond the battery itself, integration with surrounding system components is critical. Our BMS solutions support standardized industrial communication protocols such as CANBUS (including J1939), RS-485, and MODBUS, as well as isolated proprietary interfaces for secure, interference-resistant operation in high-noise environments. This enables reliable communication with power electronics such as inverters, charge controllers, DC/DC converters, and supervisory control systems. For hybrid and multi-source applications, the BMS facilitates coordination across multiple power pathways, ensuring system stability and performance.

The modular nature of our integration model allows us to rapidly tailor the BMS to unique system architectures. Whether for stationary storage, mobile platforms, marine systems, or off-grid microgrids, we provide configuration flexibility at both the hardware and firmware levels. Custom mappings, voltage thresholds, and control commands can be aligned with your system’s behavior to ensure smooth interoperability—accelerating development, minimizing integration risks, and enabling fast time to market.